WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

Featuring high automation;

Superior precision;

Excellent efficiency;

User-friendly operation.

Email: info@hx-machinery.com

WhatsApp: 0086 15522419684

The L-Shaped is a state-of-the-art angle roll forming machine specifically engineered for the high-volume production of L-shaped steel framing members, commonly known as track or runner channels. This advanced angle roll forming machine utilizes a continuous cold-rolling process to transform pre-slit steel coils into precise and consistent L-shaped profiles with remarkable speed and accuracy. It is the cornerstone of modern, automated production lines for light gauge steel (LGS) framing in construction and modular building industries.

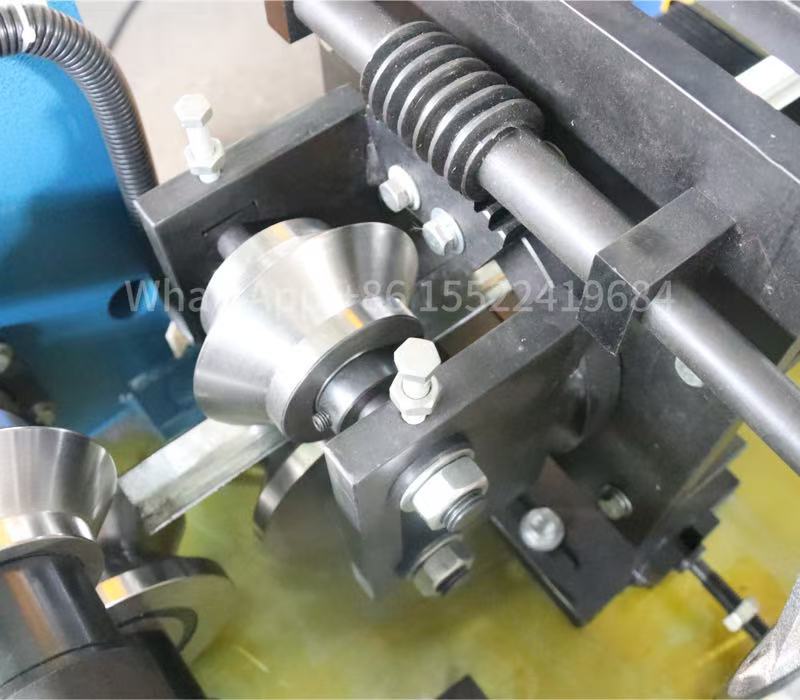

The core of this system is its robust angle roll forming machine station, which progressively shapes the metal through a series of precision-engineered rolls. Unlike simple brake presses, this method ensures a uniform profile along the entire length of the coil, eliminating inconsistencies and weak points. The machine is capable of processing various steel grades and thicknesses, offering exceptional flexibility to meet diverse project specifications.

· High Efficiency & Productivity: Designed for uninterrupted, continuous operation, this machine dramatically increases output compared to traditional manufacturing methods, significantly reducing production time and labor costs.

· Superior Precision & Consistency: The multi-stand roll forming process guarantees that every L-shaped profile produced has exact dimensional accuracy, uniform angles, and a smooth, high-quality finish, which is critical for seamless assembly on-site.

· Robust & Durable Construction: Built with high-strength components and a rigid frame, the machine ensures long-term reliability, minimal maintenance, and stable performance even under heavy-duty operating conditions.

· Remarkable Flexibility: With quick-change tooling and adjustable roll stands, the machine can be easily reconfigured to produce different sizes of L-shaped profiles, allowing manufacturers to respond swiftly to changing market demands.

· Automated & User-Friendly: Integrated with a modern PLC control system, the operation is simplified. The automation allows for precise control over parameters like cutting length and production speed, ensuring repeatable quality and reducing the potential for operator error.

| Dimension | 4500 x 900 mm |

| Weight | 1600 Kg |

| Color | Primarily Blue + Yellow |

| Feeding Thickness | 1.35 - 2.0 mm |

| Punching & Cutting | Servo tracking cut-off,servo motor power 1.5 kW |

| Shear Blade | Cr12MoV shear blades, heat treated to HRC 58-60℃ |

| Rows | 8-roll forming |

| Uncoiler | 1.5 ton vertical manual decoiler, 1.5 x 300 mm |

| Receiving Rack | 3-meter receiving rack (Manual, 1 set) - Color to be changed to blue, matching the equipment |

| Shaft Diameter | 55mm solid shaft with locking screw, made of high-quality 45# steel, forged parts |

· Reduced Material Waste: The continuous coil-to-length processing method minimizes scrap generation, leading to substantial material savings and a more cost-effective, environmentally conscious production cycle.

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.