WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

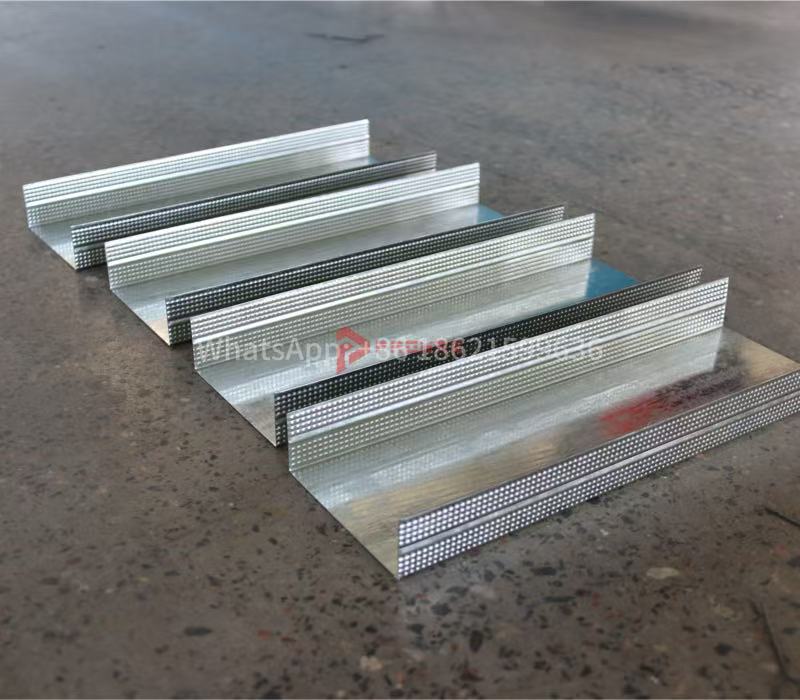

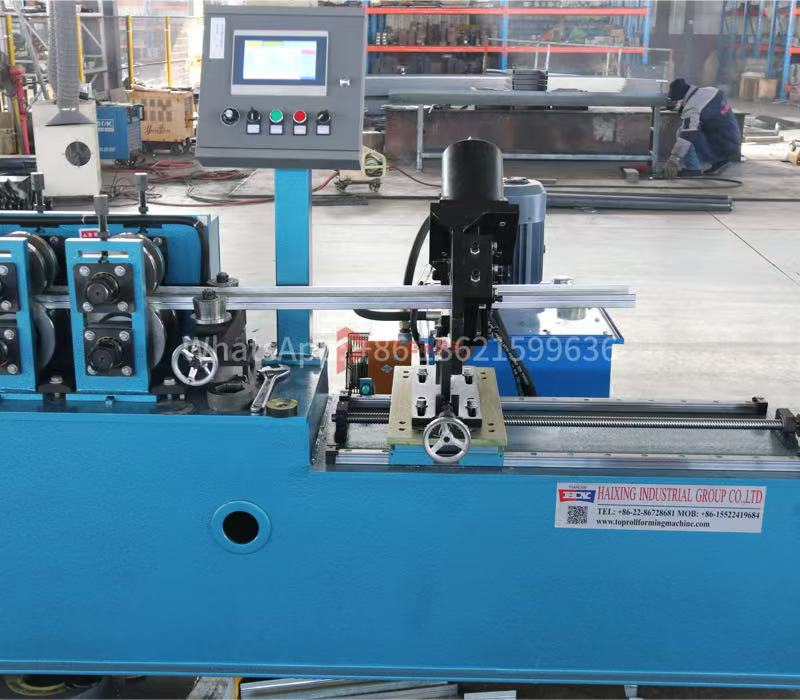

This advanced U-track roll forming machine is engineered for the continuous, high-volume manufacturing of U-shaped steel tracks. As a versatile track roll forming machine, it effortlessly processes various galvanized steels, cold-rolled coils, and other metal strips into precise and consistent U-track profiles. The machine's robust construction ensures long-term reliability and minimal maintenance, making it an indispensable asset for construction, ceiling, and partition systems.

· High Efficiency & Automation: Our track roll forming machine is designed for seamless integration into automated production lines, significantly boosting output and reducing labor costs.

· Precision Engineering: Equipped with high-grade rollers and a sturdy frame, it guarantees consistent profile dimensions, excellent shape retention, and superior product quality in every U-track produced.

· Quick-Change Flexibility: The tooling can be changed rapidly, allowing for swift transitions between different sizes and specifications of U-tracks, which maximizes production flexibility and minimizes downtime.

· Durability & Low Maintenance: Built with heavy-duty components and precision bearings, this U-track roll forming machine ensures stable performance over a long service life with minimal operational costs.

| Dimension | 4700*900 |

| Weight | 2000kg |

| Color | Blue |

| Feeding Thickness | Feed Thickness: 0.45-0.9mm |

| Punching & Cutting | Servo tracking cutting, servo motor power 1.5 kW |

| Shear Blade | Cr12MoV shear blade heat treatment HRC 58-60°C |

| Rows | 10 Row Type |

| Uncoiler | 2.5-ton vertical manual decoiler 2.5T * 300mm |

| Receiving Rack | 1 unit of 3-meter material receiving rack - Blue, same as the equipment (Manual, 1 set) - Grey changed to blue, same as the equipment |

| Shaft Diameter | 50mm solid shaft with locking washer, high-quality 45# steel, steel forged part |

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.